- Product Name:

AAC Block Production Line

- Model: AAC Brick Production Line

Contact Us

Contact Us

Product Details

Product Details

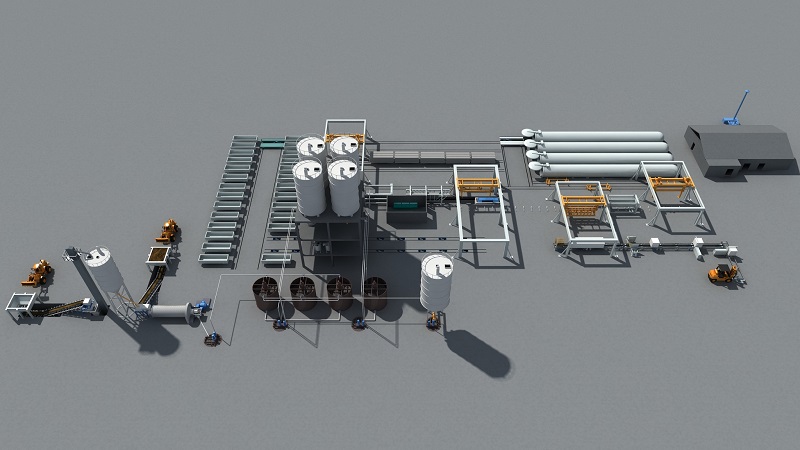

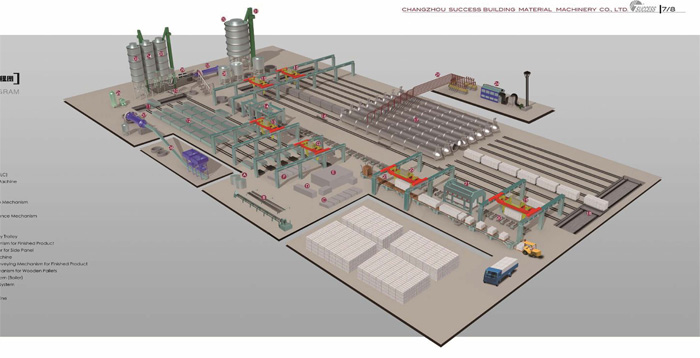

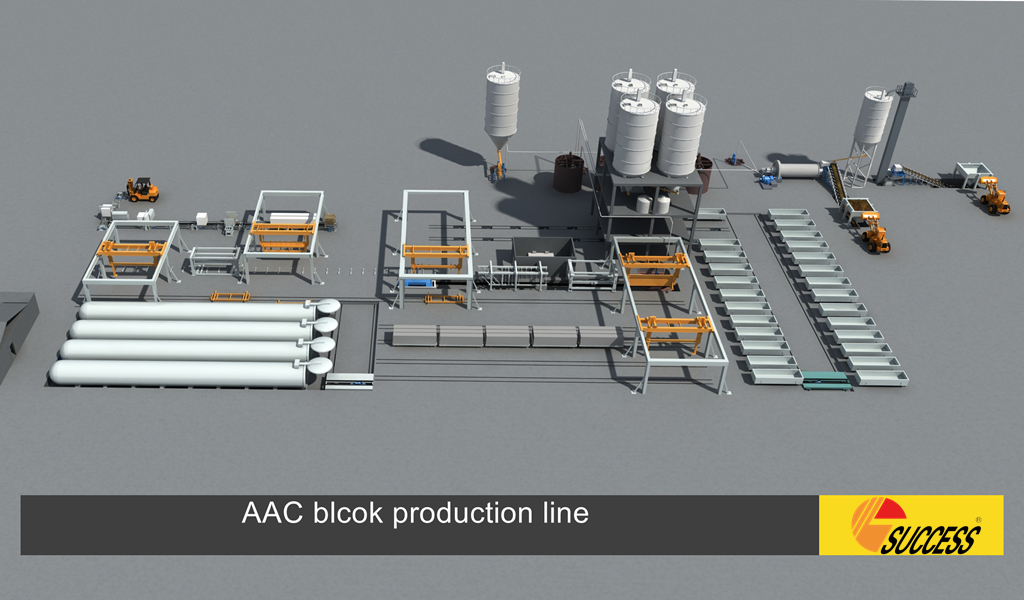

Changzhou Success Building Material Machinery Co.,Ltd is a professional and experienced manufacturer of autoclaved aerated concrete(AAC) block production equipment. The AAC production line we design exclusively for you can achieve annual output (production capacity) of 50,000m3 100,000m3, 150,000m3, 200,000m3, 250,000m3, 300,000m3 AAC blocks according to your business plan. So far, our products have been exported to over 15 countries and regions across the world. The whole production line includes mixing and pouring machine, cutting machine, autoclave,separating machine and so on. We not only supply single equipment but also undertake turnkey project.

The machine has automation technology, which can quickly and efficiently complete operations such as automatic feeding, conversion, feeding and masonry. It can accurately control the spacing between the masonry lining and the modules, and ensure that the size of each masonry block is consistent, thereby improving the efficiency of masonry and reducing construction costs.In addition, it adopts a programmable control system to realize touch operation, which can intuitively realize product quantity calculation, and the operation is more convenient and simple.The AAC Block Production Line of Changzhou Success Building Material Machinery Co., Ltd can meet the masonry needs of various building components. It is an efficient masonry equipment, which can make your building quality more accurate, improve the construction process, and save construction costs.

![]()

1.Stocking and supplying raw materials

2.Processing raw materials

3.Batching and pouring

4.Cutting

5.Grouping and maintaining process

6.Steaming in autoclaves

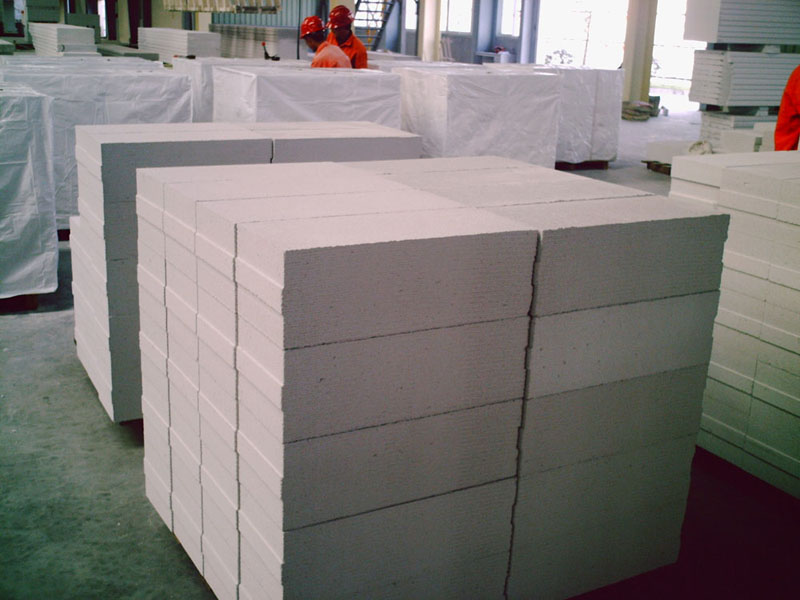

7.Final products packaging

1.Production Line Design

Including: drawing of plant working process , drawings of land construction, drawings of power working, drawings of driving force for working, drawings of anti-dust, drawings of water supply and drainage, and drawing of air pipeline construction.

2.Technical Guidance of Building Factory

Including: consultation of facility, Equipment installation guide, constitution the production preparation, etc.

3.Providing the technical information of setting up factory

Including: part of the factory management system, all posts accountability of production line, process rules, safety rules, setting a quota of staff and posts, pre-production tools directory, laboratory instruments, product catalogs, and test methods.